|

|

||

|

Made in Russia! |

Warranty and postwarranty service |

|

Made in Russia! Warranty and postwarranty service |

![]() Request form

Request form

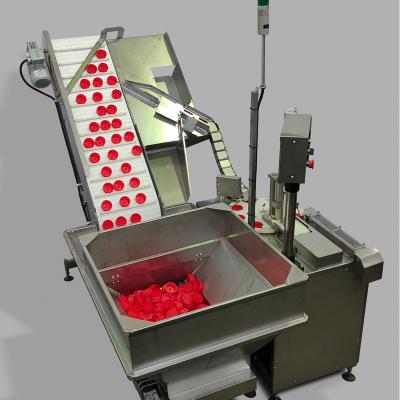

This machine carries out automatic insertion of the liner into the lid(plug, cap). The operator loads covers the orienting elevator, loads liners in the machine and changes tank for finished lids. Machine carries out feeding and orientation of the lids, feeding of the liners, centering and assembling of the components, control of the inserted liner, counting of finished products, and stoppage after reaching the specified amount of finished lids. Machine does not require constant attention of the operator. One operator can handle few machines and pack products in the cardboard boxes. The machine is able to put liners for induction sealing, circle or ring shaped liners made from foamed polymer.

This machine consists of orienting elevator and assembly module. Assembly module contains executive mechanisms, air preparation tools, sensors, hopper controller, managing controller and remote control with display.

The CAM-07 may be used for assembling few types of products, special changeover kits may be manufactured for that purpose. It takes only 20 minutes to readjust the machine. Machine can be beefed up with pre-hopper, adhesive equipment, device for cutting out liners from the roll. We will be glad to modify equipment in accordance with customers’ special requirements.

For preliminary information about price and delivery time you can fill in the query form and send it with blueprints to our e-mail. For more accurate information on the price and delivery time you need to us with product samples. This is necessary in order to take into account technological tolerance, eliminate possible misunderstandings and ensure eventually a stable, productive work of the equipment with your products. Testing performance and acceptance tests are carried out on the customer’s products. Thus you can get the equipment that is fully operational and ready for work.